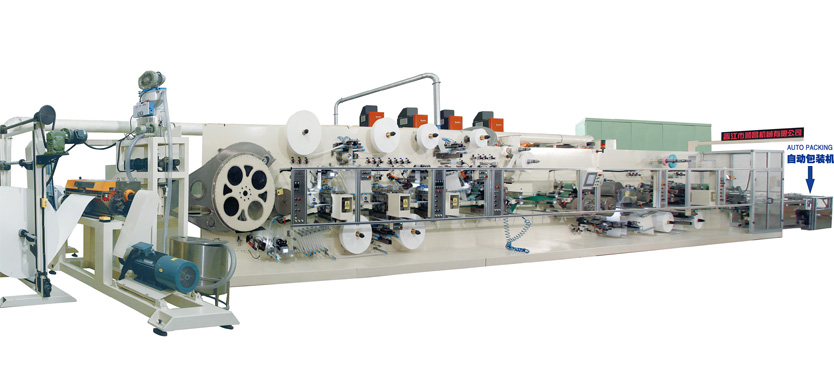

Pantyliner Production Line

Pantyliner Production Line

Main Technical Data

Raw material specifications

|

Working Speed(Production speed)

|

800pcs~1500pcs/minute

|

|

Working Speed(Linear web speed)

|

Up to 220meters/minute

|

|

Power supply

|

380V 50HZ, Tri-phase

|

|

Installation power capacity

|

135~185KW

|

|

Air consumption

|

1800~4800l/minute

|

|

Qualified rate

|

≥98%

|

|

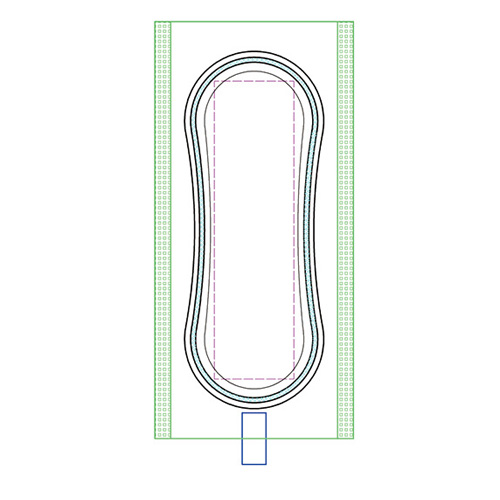

Product width(min~max)

|

65~100mm

|

|

Product length(min~max)

|

155~200mm

|

|

Dimensions(L×W×H, Meters)

|

L: 20~25 W: 4.5~6 H: 3~4.5 |

|

Technical features

Compact design, easy operation&maintenance Modular design, for future upgrading Low consumption, high efficiency Servo or frequency inverter transmission Touch screen for man-machine conversation Auto record and calculation of process data Main raw material auto splicing at zero speed Inverter or servo unwinding with tension control Web guiding controller Sensor quality control systems Material broken and lost inspection, auto machine stop and defective products auto rejection Easy size changing and manufacture CE approval |

Basic process configuration:

High speed pulverizer(untreated pulp is allowed) Fluff forming unit SAP dosing unit Raw material feeding units Inner cutter unit Product 90°transverse turning Final cutter unit Pouch film application unit Air application unit Safety protection unit |

Optional process configurations:

Aloe/perfume application unit Gravimetric SAP dosing unit Camera quality detection unit |

|

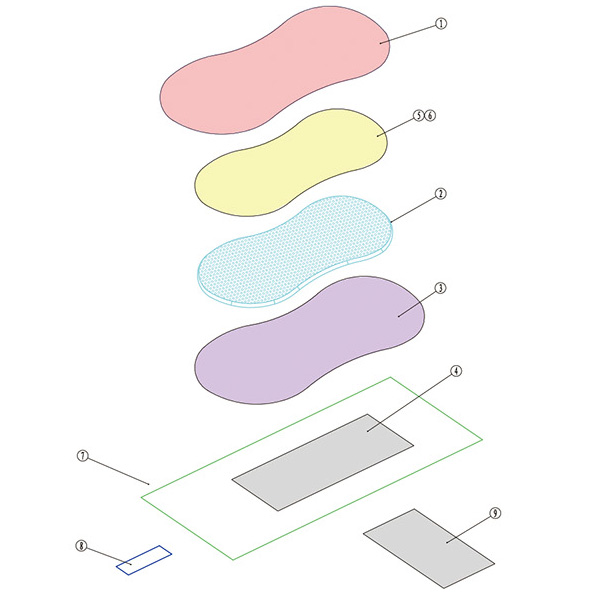

Item Number

|

Raw material layer

|

|

1

|

Hydrophilic N.W.(for top sheet)

|

|

2

|

Hydrophobic N.W.(for standing cuff)

|

|

3

|

Acquisition&distribution layer N.W.

|

|

4

|

Fluff core pad

|

|

5

|

SAP(super absorbent polymer)

|

|

6

|

Upper tissue

|

|

7

|

Lower tissue

|

|

8

|

Back sheet PE

|

|

9

|

Back sheet(clothlikes)

|

|

10

|

Magic tape(with hook)

|

|

11

|

Frontal pad

|

|

12

|

Leg elastics

|

Mobile

Mobile WeChat

WeChat

shunchangjx@hotmail.com

shunchangjx@hotmail.com 0086-595-8572785

0086-595-8572785